|

|

|

|

|

|

|

|

|

|

|

Roger asked me if I'd have the time to modify his web page to let you all know what's going on.

He asked me extend his apologies to readers of this site for not having the capacity to do this update himself, for reasons that will become clear later in this post. So, if, like me, you wondered where the heck Roger has been all this time, he's been busy, and disconnected. So, please don't feel ignored or snubbed.

A friend of mine and I recently had the pleasure of being able to visit Roger, his wife, and Roger's multiple impressive workshops. Before this visit, I had read all I could find about Bourke engines, and remained skeptical that such a miraculous beast could really live up to the promises that Russel Bourke had claimed. The complete lack of updates to this website further encouraged my skepticism; why would someone who clearly has a dynamometer mounted correctly, not run and publish BSFC tests?

When I actually asked Roger this question, I regretted it about 10 words into his answer. To massively paraphrase his response: "The road to reliable, complete, and credible proof is paved with spare parts, patience, time, and money, but mostly time and money, neither of which I have in abundance." Roger also raised the point that he'd like to not repeat some of the mistakes that Bourke apparently made, such as singing to the world about miracles before the test results were really irrefutable. Proper testing, and not just publishing results from some haphazard Sunday afternoon fiddling would make matters worse, not better. After peeking into Roger's world on my recent visit, this answer makes a lot of sense to me.

Google MAPS was of no use to us, while trying to locate and navigate the remote corner of Maine that Roger lives and works in. Once we finally stumbled upon Roger's place we were generously shown around. Roger showed us Wheeler One - his fairly large RV service shop that "pays the bills". Folks, let me tell you this place was PACKED wall to wall with motorcycles, mini-ATVs, and other RVs parts I'm not talented enough to identify. I stared, mouth-agape in amazement that one man runs this place and yet manages to stay sane. As Roger showed us around this impressive and self-built establishment, he pointed to and told us about some particularly challenging rebuilds he's recently finished. Listening to Roger, I realized that in addition to everything else, he was the very best mechanic I've ever met. I own three motorcycles and a car, and actually entertained the notion that it would probably benefit me to pack them all together, and ship them the ~500 miles to Roger such that he can really fix/tune them properly, like no mechanic in my hometown ever could or would. Slowly, as Roger pointed out the various tribulations involved in starting a business like this, including actually building the shop, developing a customer base, and actually running the day to day, I began to understand why the Bourke engine has not progressed in the way the rest of us wish it would; Pay the bills, THEN save the world.

After the tour of Wheeler One, we were given an impromptu Bourke Engine Replication class back at Roger's other workshop. Roger showed us the various Bourke original engines, parts, and even the VAUX engine he's managed to acquire over the years. The lesson included a brief history of his work thus far, and a show-and-tell session about the various crank shafts, piston heads, bearings and whatnot that had been incorrectly specified, or incorrectly machined such that they failed in one way or another. It was a concentrated lesson in humility; if you get the flexibility of a piston head incorrect, you will most likely wreck your engine. I had no idea from the drawings that piston heads were even supposed to be flexible.

I wondered briefly if that means the Bourke engine is just too finicky, thus it would take years to reproduce. After re-reading the Bourke manual over again, I came to the conclusion that the reason so many others have failed to reproduce Bourke's results is not because the engine is finicky, it's because they didn't understand the original very well. There really IS a reason for every detail - if you deviate before you understand those reasons, you may fail. It caused me to finally understand why it may take a few tries to have someone machine just the correct part, and why, therefore, with limited budget and time, it takes so long to build and test a correctly working engine.

When I asked Roger for the secrets to successfully build your own Bourke engine, I received a heavy sigh, and a list of tips that boils down to:

i) Walk before you run. Don't "improve upon" the Bourke formula before you even replicate it.

ii) Take the time to really understand the Bourke formula. This may seem like a repeat of #1, and perhaps it is, but it's important enough to be worthy of repetition. This is the lesson I received, for example, when examining the large assortment of burned, broken, or smashed piston heads because their design exercised a little too much creativity.

iii) Measure twice, cut once. If, for example, your triple slipper bearing has 9/1000" play, your engine will most likely implode.

iv) Take your time when assembling your engine. If you run something that you think is "good enough", without even a proper leak down test, you're wasting your time, parts, and probably the nice décor on your walls. If the pressure test shows differences in compression, your engine probably won't run. Find and fix the mistake before you fire it up.

So, friends, I suggest we be patient a little longer. Roger's replica engine looks like it's nearly ready to run again, so I don't know about YOU all, but I, for one, am on the edge of my seat. I hope you all join me in wishing Roger well, such that he'll have time to finish his engine, run the tests, and generously share his findings with us in the next few months.

For Bourke Engine.net click on the picture

Last updated, April 24, 2007

Please note new e-mail address at botom of page.

Philosopher Bertrand Russell once said, "The resistance to

a new idea increases as the square of its' importance".

Please watch for "Bourke 101". Written by Bob Zigler, this

summary will answer frequently asked questions and provide

the "Bourke Cycle" basics.

As my opener, I am displaying my most prized possession, the first 30 cubic inch internal combustion engine sold by Russell Bourke.

Why is this engine unique?

Ultra low exhaust gas temperature-more energy converted to useful work.

Ultra lean mixture-more economical without power loss.

Uses lower octane fuels-avoids toxic fuel additives.

Attributes more closely satisfy elements of ideal I/C engine:

- maximum pressure attainable in a cylinder

- quickest expansion

- minimum heat loss

- best mechanical advantage

- fewer moving parts

I have just recently gotten a domain, and plan to publish my experiences with Russ Bourke's engines and improved Otto Cycle-the "Bourke Cycle". Drop me a note, and stop-by often. Roger Richard

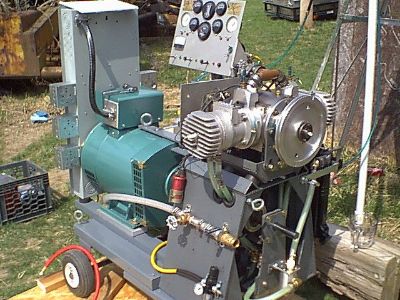

Bourke 30" homebuilt engine powering a 24 kW generator, 3.25/1 belt reduction. Recent runs include use of jet-A, white gas mix. Improvements to the cooling system have made a big difference in reliability and predictable running.

View of standard automotive radiator, Go Power water brake mounting plate and stub shaft pillow block. Someday, I'll have to make a list of all the readily available parts used to get the 24 kW stand together. I believe this work typifies the "homebuilt" spirit.

View of standard automotive radiator, Go Power water brake mounting plate and stub shaft pillow block. Someday, I'll have to make a list of all the readily available parts used to get the 24 kW stand together. I believe this work typifies the "homebuilt" spirit.

Thanks to Dan Hester, Waterford, Mich. for the radiator, gear

pump, the invaluable technical assistance, and the "just-in-time"

machine work. Recent upgrades were completed in Machiasport, Me.

and Waterford, Mich. Fuel consumption testing is underway.

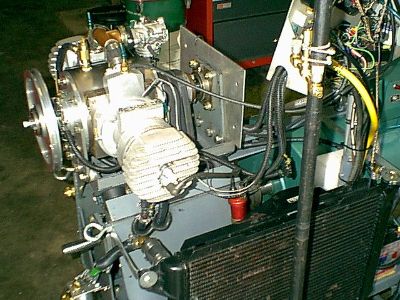

Because I used steel for the camcase, it was necessary to run the case oil through the transmission section of the donated car radiator to prevent heat build-up in the bottom-end oil. The new cooling components are "off the shelf" and commonly available.

Because I used steel for the camcase, it was necessary to run the case oil through the transmission section of the donated car radiator to prevent heat build-up in the bottom-end oil. The new cooling components are "off the shelf" and commonly available.

30" OEM at Oshkosh 2003

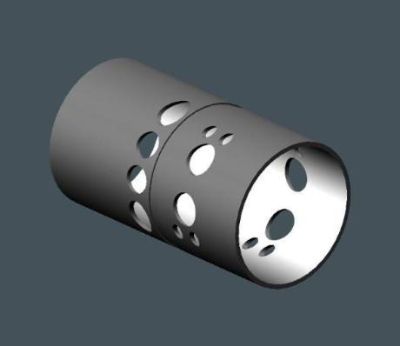

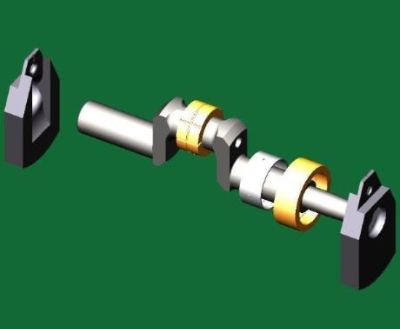

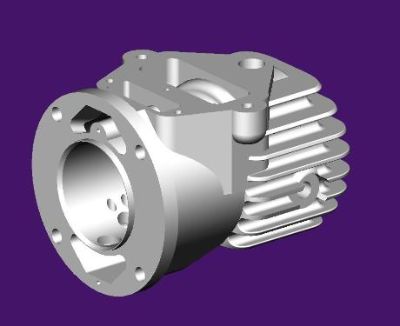

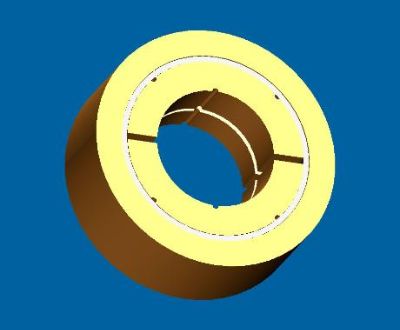

There has been strong demand for our CAD models. Contact me via e-mail, and I will supply you with a test file. The Solid Works "viewer" is a free download at their site. The viewer will enable you to do basic operations such as rotation, shading, etc. This is a teriffic learning tool for those wanting a closer look at the part files.

There has been strong demand for our CAD models. Contact me via e-mail, and I will supply you with a test file. The Solid Works "viewer" is a free download at their site. The viewer will enable you to do basic operations such as rotation, shading, etc. This is a teriffic learning tool for those wanting a closer look at the part files.

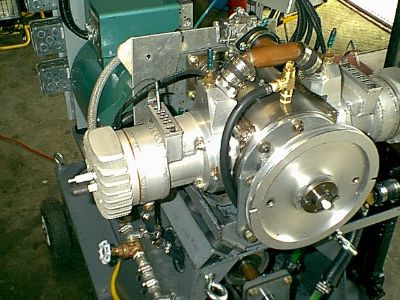

Looks like a crankshaft, functions as a camshaft. a high speed

reverse roller camshaft.

All Bourke engine components are ruggedly constructed.

Many parts are "off-the-shelf".

This is the "triple slipper" bearing. It is the only bearing

design suitable for the load and speed demands of the

crosshead assembly.

Cast iron cylinder liners are inexpensive and easy to machine.

rogerrichard@verizon.net